REESE’S LAW – 16 CFR 1263

On August 16, 2022 U.S. President Joe Biden signed a law that protects children and other consumers against hazards associated with the accidental ingestion of button cell or coin batteries. “Reese’s Law” was created in honor of Reese Hamsmith, an 18-month-old child who died in 2020 after ingesting a button cell battery from a remote control.

On September 21, 2023 U.S. Consumer Product Safety Commission (CPSC) published a final rule with provisions outlined for button and coin cell batteries found in common household products.

The final rule consists of two Federal Register notices: one incorporating the 2023 version of the industry standard UL 4200A as the federal mandatory rule (the adoption of 16 CFR 1263), and the other introducing additional packaging and labeling requirements for button and coin batteries not covered by UL 4200A.

These requirements do not apply to toy products for children under 14 if the products comply with the ASTM F963 Toy Safety Standard.

The effective date of 16 CFR 1263, unless the CPSC receives and accepts “significant adverse comments” by October 23, 2023, but the Commission is granting a 180-day transitional period of enforcement discretion from September 21, 2023, through March 19, 2024.

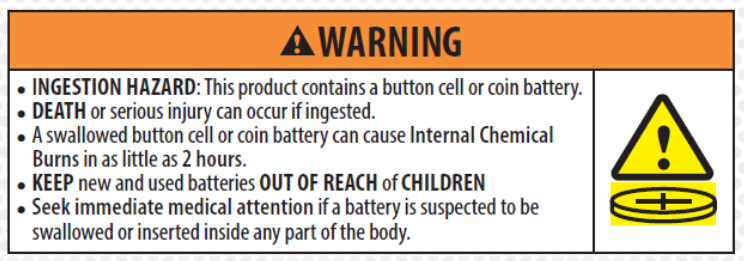

Marking– Packaging

Except in cases product without packaging or packaging display panel is very small, the principal display panel shall contain the warning label. The icon shall be at least 7 mm in width and 9 mm in height. The icon shall be at least 8 mm (0.31 in) in diameter. The text in the warning label shall be as shown. When on a printed label using more than one color the marking must use colors as shown.

Marking– Product

Except the cases when the product has very limited space, consumer products shall be marked with a warning label on the product display panel that alerts the consumer of the presence of a button cell or coin battery. The warning text shall include the safety alert symbol, signal word, and text. When on a printed label using more than one color the marking must use the color as shown.

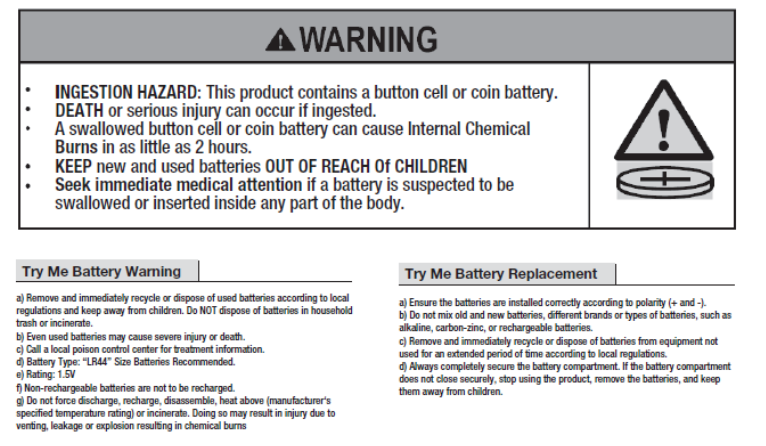

Instructional Literature Requirements

Instructions and manuals, if provided, shall include all of the applicable markings and the statements noted below. If instructions and manuals are not provided, the statements shall be present on the principal display panel or secondary display panel of the consumer product packaging, or if there is no consumer product packaging, the accompanying hang tag or sticker label.

a) The statement “Remove and immediately recycle or dispose of used batteries according to local regulations and keep away from children. Do NOT dispose of batteries in household trash or incinerate.”

b) The statement “Even used batteries may cause severe injury or death.”

c) The statement “Call a local poison control center for treatment information.”

d) A statement indicating the compatible battery type (e.g., LR44, CR2032).

e) A statement indicating the nominal battery voltage.

f) The statement “Non-rechargeable batteries are not to be recharged.”

g) The statement “Do not force discharge, recharge, disassemble, heat above (manufacturer‘s specified temperature rating) or incinerate. Doing so may result in injury due to venting, leakage or explosion resulting in chemical burns.

Products with replaceable button/coin cell batteries shall additionally include

a) The statement “Ensure the batteries are installed correctly according to polarity (+ and -).”

b) The statement “Do not mix old and new batteries, different brands or types of batteries, such as alkaline, carbon-zinc, or rechargeable batteries.”

c) The statement “Remove and immediately recycle or dispose of batteries from equipment not used for an extended period of time according to local regulations.”

d) The statement “Always completely secure the battery compartment. If the battery compartment does not close securely, stop using the product, remove the batteries, and keep them away from children.”

Performance

Protection from Ingestion or Aspiration of Button/Coin Cell Batteries

Products shall not present a risk of unintentional access by children to button/coin cells. Button/coin cell batteries shall not be accessible or liberated from the product as a result of mechanical abuse tests in applicable safety standards for the product, and products with button/coin cells shall comply with the tests in 6.2 – 6.4.:

One test sample shall be subjected to the following pre-conditioning conditions in sequence prior to testing in 6.3 and 6.4, as applicable:

a) Stress Relief Test

- A sample of the complete product is to be placed in a circulating air oven for a period of 7 h. The oven temperature is to be set to the higher of (1) or (2) below. After removal from the oven, the sample is permitted to cool to room temperature.

1) 70°C (158°F); or

2) 10°C (18°F) higher than the maximum temperature of thermoplastic enclosures, battery compartment door/covers, or battery compartment door/cover mechanisms during the most stringent normal operation of the device.

b) Battery Replacement Test

- The battery compartment door/cover shall be opened and closed, and the battery removed and replaced, for a total of 10 cycles. The process shall simulate replacement according to the manufacturer’s instructions.

Abuse Tests

The tests in 6.3.2 – 6.3.4 shall be performed sequentially, as applicable, on one pre-conditioned sample of the product. After all test conditions have been completed, compliance is checked by 6.3.5.

Drop Test

Portable devices are subjected to drop tests from a height of 1.0 m (39.4 in) onto a horizontal hardwood surface in positions likely to produce the maximum force on the battery compartment or enclosure.

Portable devices are subjected to 3 drops, except hand-held products are subjected to 10 drops. The hardwood surface shall be at least 13 mm (1/2 in) thick, mounted on two layers of nominal 19 mm (3/4 in) thick plywood, placed on a concrete or equivalent non-resilient surface.

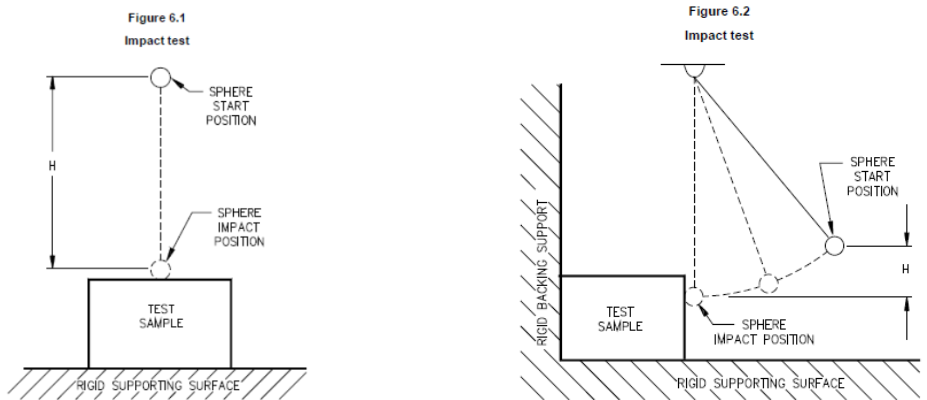

Impact Test

The enclosure or battery compartment door/cover shall be subject to three, 2-J (1.5-ft·lbf) impacts. This impact is to be produced by dropping a steel sphere, 50.8 mm (2 inches) in diameter, and weighing approximately 0.5 kg (1.1 lb) from the height required to produce the specified impact or the steel sphere is to be suspended by a cord and swung as a pendulum, dropping through the vertical distance required to cause it to strike the surface with the specified impact. The steel sphere is to strike the battery compartment door/cover perpendicular to the enclosure surface.

Crush Test

The sample is to be supported by a fixed rigid supporting surface, in positions likely to produce the most adverse results as long as the position can be self-supported. A crushing force of 330 ±5 N (74.2 ±1.1 lbf) is applied for a period of 10 s to the exposed surfaces. The force is to be applied by a flat surface measuring approximately 100 by 250 mm (3.9 by 9.8 in). If a child can grasp any part of the battery compartment enclosure on a consumer product including the door or cover, with at least the thumb and forefinger, or using teeth, apply the following tests

Torque Test

- Apply the Torque Test for Removal of Components per ASTM F963, to the battery compartment enclosure, using a torque of at least 0.50 Nm (4.4 in-lbf).

Tension Test

- Apply the Tension Test for Removal of Components per ASTM F963, to the battery compartment enclosure, using a force of at least 72.0 N (16.2 lbf).

Compliance test

After the tests of 6.3.2 – 6.3.4B, a force of 50 +10/-0 N (11.2 +2.2/-0 lbf) is applied for 10 s to the battery compartment door/cover or enclosure by a rigid test finger according to Test Probe 11 of IEC 61032. The probe is applied at the most unfavorable place and in the most unfavorable direction. The force shall be applied in only one direction. A battery compartment door/cover shall not open and shall remain functional. The battery shall not be accessible.

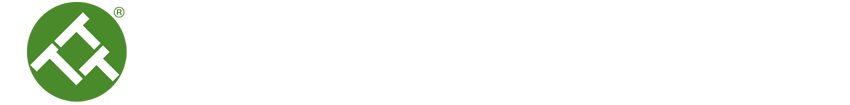

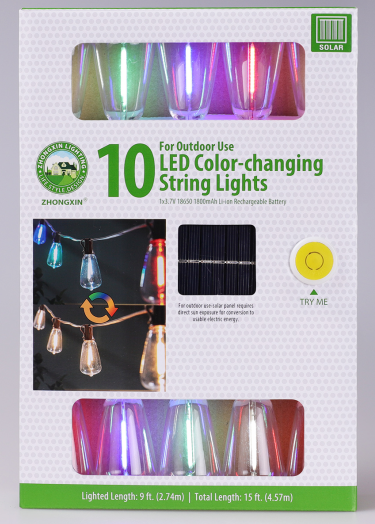

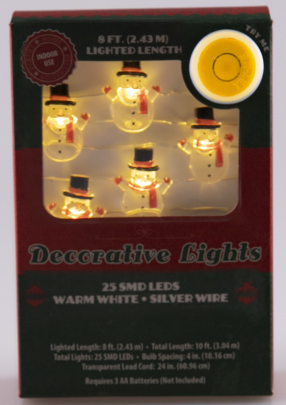

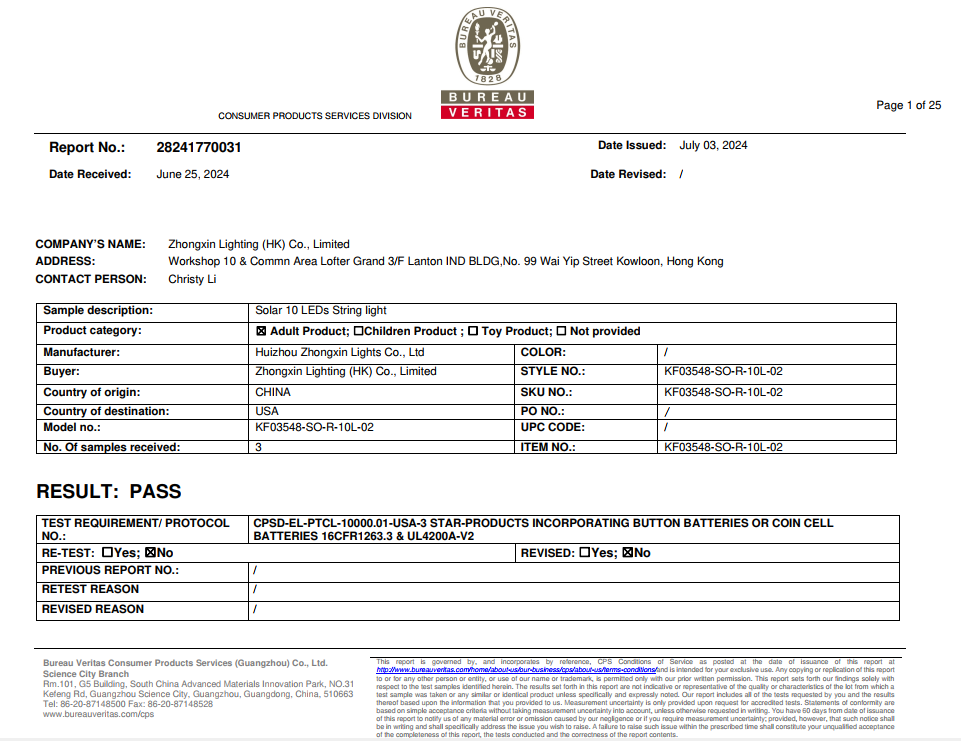

Zhongxin Lighting Passed the testing – TRY ME Part

Learn More About ZHONGXING Products TRY ME on Package

People also ask

Post time: Aug-19-2024